News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Reasonable suggestions for preventing metal corrosion

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-08-10

- Click:0

By adding other elements, the internal structure of the metal is changed

For example, chromium and nickel are added to ordinary steel to make stainless steel.

⒉ The metal surface covered with a protective layer, so that the metal and air and water vapor isolation, effectively prevent the chemical corrosion of metal materials.

The protective layer covering can be divided into three categories: one is the non-metallic protective layer, such as paint, spray paint, enamel, ceramics, glass, asphalt, polymer materials (such as plastic, rubber, polyester); The second is the metal protective layer, such as with strong corrosion resistance metal or alloy, covering the protected metal surface, covering methods are electroplating, hot spraying, vacuum plating, etc.; The third is the metal oxide protective layer, such as the use of baking blue technology, so that the metal surface oxide protective layer.

C. Electrochemical Protection Act

Because the metal element can not gain electrons, as long as the metal is protected as an electrochemical device for the reduction reaction of a pole - cathode, can cause metal electrochemical corrosion of the galvanic cell reaction to eliminate.

The specific methods are:

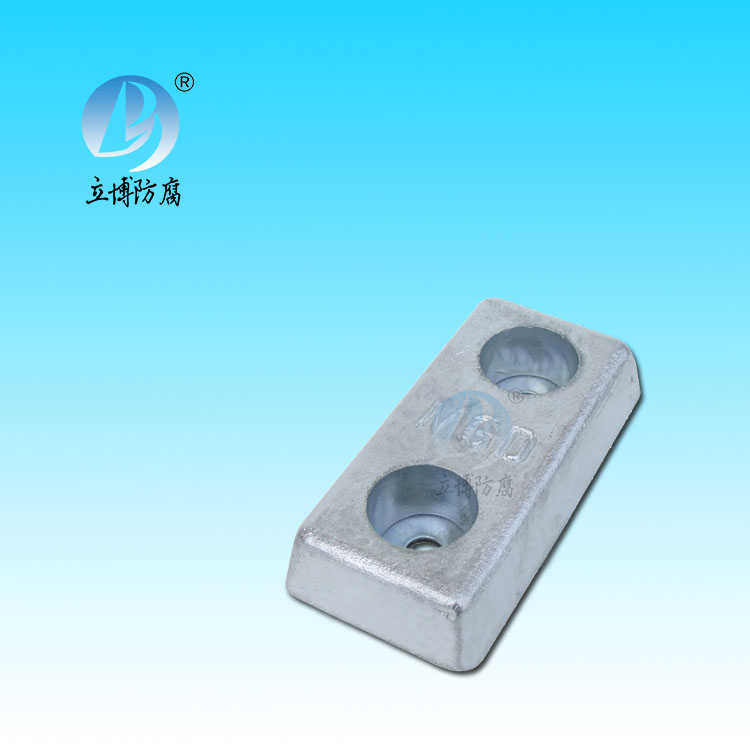

(1) Sacrifice the anode cathode protection law: this method applies the principle of galvanic battery, let the protected metal as a positive electrode, and find a strong active metal as a negative electrode. For example, in the boiler wall, the hull of a ship with a number of zinc blocks, can protect steel equipment. Electrode reactions occurring:

Negative: zinc - 2 e - - > Zn2 +

The positive: O2 + 4 e - 4 + 2 h2o - oh -

(2) Impressed current cathodic protection: this method applies the principle of electrolysis, so that the protected metal as cathode, inert electrode as an auxiliary anode, both exist in the sea water, connected to the DC power supply. Steel sluice gates, for example, can be prevented from corrosion by this method. In this method, the discharge particles on the anode are anions in seawater, and the discharge particles on the cathode are cations in seawater.

Electrochemical protection refers to the method of reducing or preventing corrosion by applying external electromotive force to move the potential of the protected metal to the corrosion free zone or passivation zone. Electrochemical protection technology is widely used in ship, ocean engineering and chemical industry. It is an economical and effective protection measure.

It is protected by corrosion inhibitors

A corrosion inhibitor is a chemical substance that, when added in small amounts to a corrosive medium, can significantly reduce the rate of corrosion of a metal. Because the amount of corrosion inhibitor is small, simple and economic, so it is a common means of corrosion prevention. There are three types of commonly used corrosion inhibitors: ① passivator ② organic corrosion inhibitor ③ gas phase corrosion inhibitor.

Modern science is developing rapidly, new anti-corrosion technology constantly emerging, accelerated the corrosion of the popularization of scientific knowledge in our country, further corrosion science in all areas of a large number of practical applications, not only is of far-reaching significance of the development of the modernization of our country, but also a large number of national energy saving, protection of resources, reduce pollution, reduce the hazard, Effective ways to improve social, economic and environmental benefits.

客服QQ

客服QQ