News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

How to prevent rust when the bottom of the ship is in the water for a long time?

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-08-08

- Click:0

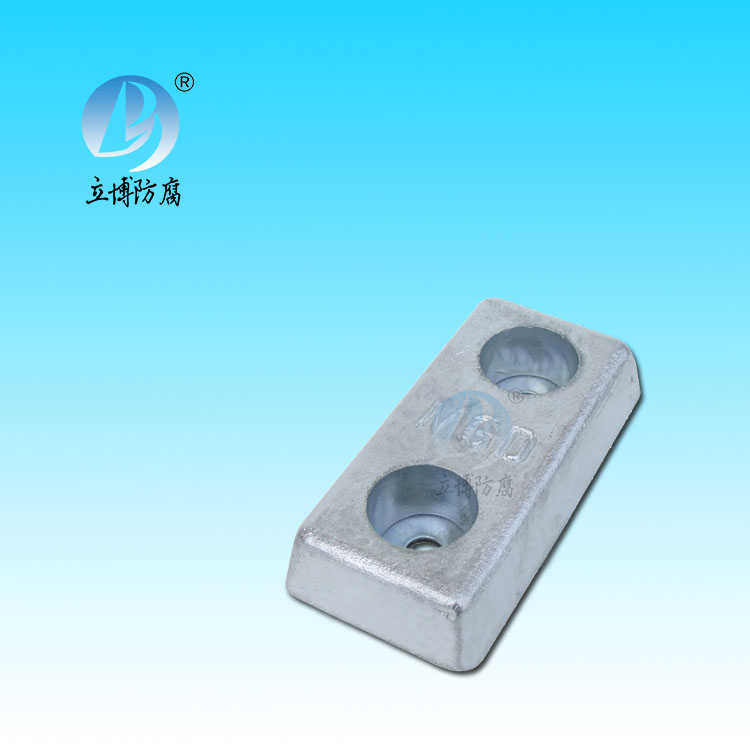

Each part of the ship is in different corrosive environment, subjected to different effects of the outside world, so the performance requirements of the coating are different, very particular. Bottom area: The bottom area is immersed in seawater for a long time, which is subjected to the electrochemical corrosion and erosion of seawater. When the ship is moored in the harbor, it will also be threatened by the pollution of Marine organisms. In addition, ships usually also use sacrifice anode or impressed current for cathodic protection, the entire underwater area of the hull will become a cathode, will appear alkaline due to excess hydrogen and oxygen ions. Therefore, the paint used in the bottom area must have good water resistance, alkali resistance, wear resistance, and the outer coating should also have anti-fouling to prevent the attachment of Marine organisms.

Waterline area: The waterline is often in the water, wash, and sunlight insolates dry-wet alternate state, namely in the splash zone this special corrosion environment, so must be used in both parts of the coating has good water resistance, weather resistance, resistance to dry and wet alternation, coating should have good mechanical strength, resistance to friction and impact resistance, when ship by cathodic protection, Also requires the paint to have good alkali resistance.

Atmospheric exposure area: ship freeboard, external superstructure, outdoor deck and deck fittings, etc in the Marine atmospheric exposure area, these areas from years in salty moisture in the atmosphere, ocean and often by sun exposure, sometimes a hit from the waves, so require coatings have excellent rust resistance, weather resistance, impact and friction performance. Because the above parts belong to the main parts of the ship's appearance, so the surface coating also needs good color retention and light retention.

客服QQ

客服QQ