News

News

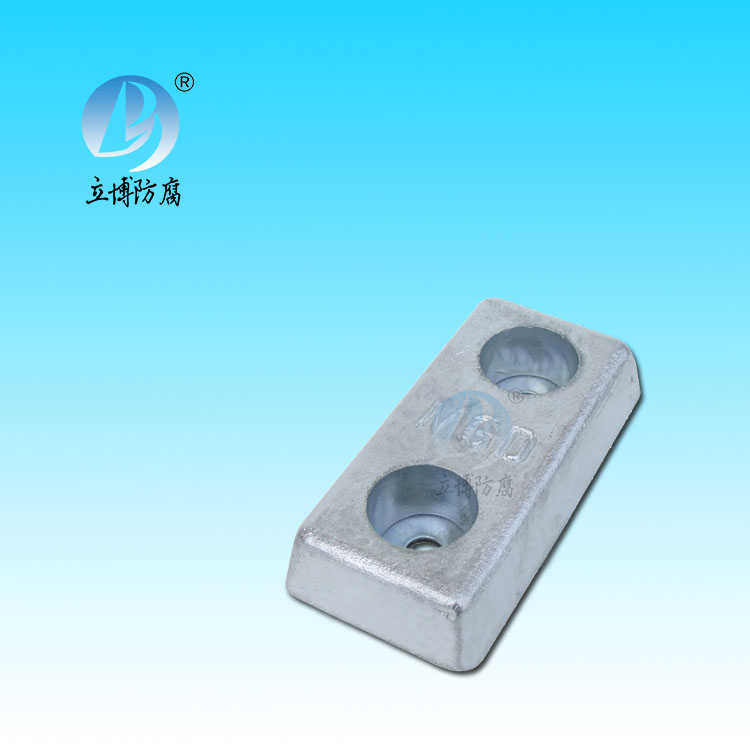

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Forging magnesium alloys can be roughly divided into three stages

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-06-11

- Click:0

(1) The first stage is a basic stage in which aluminum and zinc are mainly added to magnesium, namely Mg-A1-Zn alloy. Magnesium alloy can be formed by sand forging, lost die forging, die casting, semi-solid forging and other methods. In recent years, the new magnesium alloy die casting technologies developed include vacuum die casting and oxygen filling die casting. The former has successfully produced AM60B magnesium alloy automobile wheel and steering wheel, while the latter has also begun to produce magnesium alloy parts for automobiles.

. The tensile strength of these alloys is similar to that of forged aluminum alloys.

(2) The second stage is an improvement stage to add zirconium to magnesium, the common zirconium-containing alloy system has Mg-Zn-Zr, Mg-Re-Zr and so on. But on the whole, compared with developed countries, the comprehensive quality of die casting in China is poor (large processing allowance, high rejection rate, low alloy utilization rate, poor basic premise of forging process and equipment, serious environmental protection and energy consumption problems, lack of specialized personnel and new process and new product development capacity). China's non-ferrous metal die casting has a commensurate foundation, now has a total of about 3000 die casting factories and related enterprises, about 20 die casting machine manufacturers, an annual output of 300000T die casting.

Wrought magnesium alloys are much more widely used than wrought magnesium alloys. Adding different contents of mixed rare earth on the basis of AZ91 magnesium alloy also has significant effect on the structure and function of as-cast and soluve-aging AZ91 magnesium alloy. In order to further improve the protective effect and reduce the dosage of more expensive SF6 gas, foreign generally in SF6 gas mixed air or other dry gases such as CO: mixed gas protection effect is good, but there are the following problems:

1) Pollution of the environment, SF6 will produce S02, SF4 and other toxic gases, SF6 global change effect is 24,900 times that of CO2;

2) The equipment is complex, requiring complex gas mixing device and sealing device;

3) Erode the equipment, significantly reduce the service life of the crucible. It can be said that our existing foundation can not meet the requirements of magnesium alloy industrialization. However, the agent should be re-dehydrated before use, use will release a choking breath.

Recently, the Shanghai jiaotong university, light alloy precision forming national engineering research the central by several elements at the same time, developed a kind of flame retardant function and mechanics function are good cars in flame retardant magnesium alloy, successfully tested car gearbox shell cover industries, and the output the electronic products such as mobile phone shell, MP3 shell.

客服QQ

客服QQ