News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

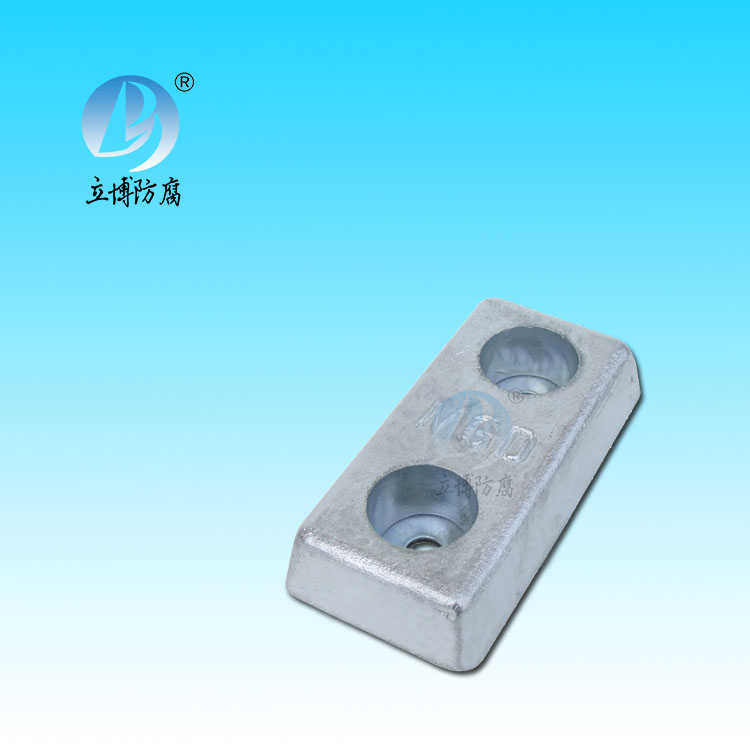

Magnesium alloy sheet

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-06-11

- Click:0

The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

Magnesium alloy sheet is the lightest metal structure material used in aircraft, spacecraft, rocket and missile manufacturing industry. Magnesium alloy products are widely used in civil and military aircraft, especially bombers. Germany was the first to produce and use aluminum-containing magnesium alloys in aircraft.

Magnesium alloy plate is a kind of plate, which is made of magnesium alloy material. China is rich in rare earth resources. In the 1970s, China developed yttrium-added magnesium alloy, which has improved its strength at room temperature and can be used for a long time at 300°C, and has been widely applied in the aerospace industry. Magnesium weighs less than aluminum, with a specific gravity of 1.8, and has a lower strength, only 200 ~ 300 mpa (20 ~ 30 kg/mm 2), and is mainly used in the manufacture of low-bearing parts.

.

Magnesium alloy sheet is composed of magnesium based alloy sheet with other elements added. Magnesium alloy is very stable in gasoline, kerosene and lubricating oil, so it is suitable for making gear casing, oil pump and oil pipe, and is used for making rocker arm, flap, hatch door and rudder surface and other flowing parts because of the small inertia force generated in rotating and reciprocating motion. For example, the fuselage section of the B-52 bomber uses 635 kg of magnesium alloy sheets, 90 kg of extrusions and more than 200 kg of castings. Magnesium alloys are also used in some parts of missiles and satellites, such as the instrument compartment, tail compartment, and engine support of China's "Hongqi" surface-to-air missile. It is characterized by: small density (about 1.8g/cm3 magnesium alloy), high specific strength, large elastic modulus, good shock elimination, bearing the impact load capacity than aluminum alloy [non-ferrous business opportunity: aluminum alloy], organic matter and alkali erosion resistance function is good. It is the lightest metal in the practical metal, high strength, high rigidity. The lightest of the practical metals, magnesium is about two thirds as heavy as aluminum and a quarter as heavy as iron. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industries.

Magnesium alloy sheet easily oxidizes and erodes in wet air, so the surface needs to be chemically treated or painted before the parts are used. Magnesium alloy has high vibration resistance, can absorb large energy when subjected to impact load, and good heat absorption function, so it is an ideal material for manufacturing aircraft wheel hub. At present the most widely used is magnesium aluminum alloy, followed by magnesium manganese alloy and magnesium zinc zirconium alloy.

客服QQ

客服QQ