News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

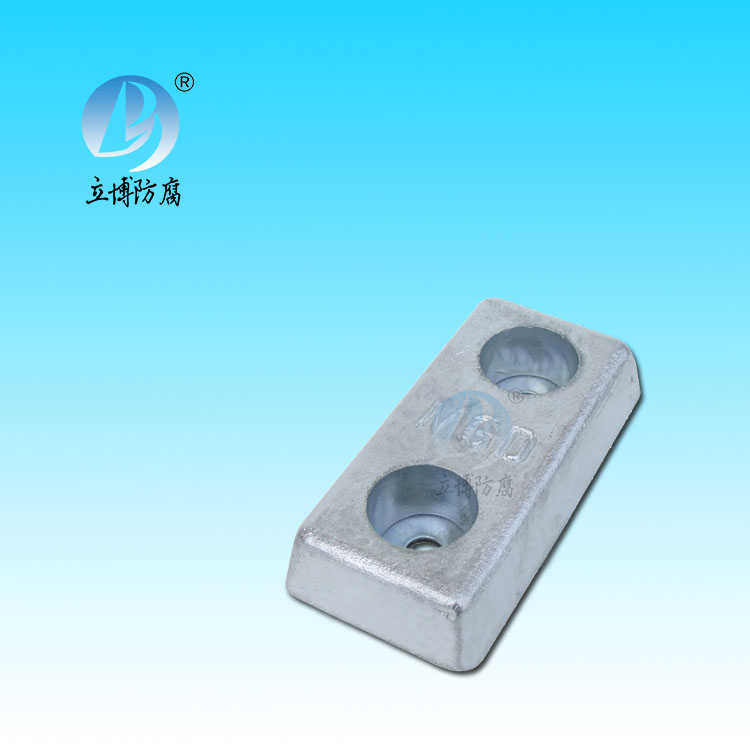

Specifications and requirements for construction of sacrificial anodes and related accessories

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-06-11

- Click:0

Installation methods and requirements for sacrificial anodes

1. The buried depth of the sacrificer anode (hereinafter referred to as anode) connection cable should not be less than 0.7m, and the cable length should leave a margin when laying.

2, the anode cable joint and pipe should be connected by thermic welding technology.

3. Before welding, the position of the pipe solder joint should be cleaned to expose the metal surface.

4. After the completion of welding, the solder joints should be treated with anti-corrosion again and strictly according to the requirements of the drawings.

5, anode bag cotton bag buried in the anode pit should be poured enough water, (packaging nylon bag should be thrown away) make it fully soaked.

6. The distance between the buried position of the anode and the pipeline is not less than 0.3m.

7, the anode should be buried below the freezing line.

8, in the buried anode group (in a connection point of the pipe is connected at the same time more than 1 set of anode is called the anode group), the distance between the anode and the anode to 2 meters is appropriate.

9, in the anode buried after backfilling, every 20~30CM backfill should be a line of compaction and watering, such as water infiltration after continue to backfill, compaction. And to saturate the filling material, fill and restore the landscape.

10. No metal structures are allowed between the buried height of the anode and the pipe.

11. A long part of the pipeline to be protected is covered by concrete, which will lead to a decrease in potential of the section. A set of sacrificial anodes should be added at both ends of the concreted position of the pipeline to compensate.

12. The correct embedding method of anodes is to alternate embedding in each set or group on both sides of the pipeline. If limited by geographical conditions, two sets of adjacent anodes must be set on the same side of the pipeline, safety requirements with anodes on both sides of the situation.

客服QQ

客服QQ