News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

Intelligent test pile

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-06-11

- Click:0

Intelligent test pile

The test pile is an essential part in the cathodic protection system, its main function is to detect the parameters of cathodic protection. Test pile also plays an important role in pipeline management and maintenance. The test pile must be installed along the pipe line according to its test function. The main components of the test pile are pile body, test wiring board, test wire and nameplate.

Pingsheng intelligent test pile automatically collects the data of pipeline protection potential, corrosion current, pipeline spontaneous potential, anode spontaneous potential and the voltage of the equipment's own battery regularly every day, and uploads the data to the cloud server regularly through the 4G/ NB-iot network.

The oil and natural gas long distance transportation pipeline mostly adopts anticorrosive coating and cathodic protection technology to prevent the anticorrosive coating from aging. Negative potential is applied to the pipeline by means of potentiostatic instrument or sacrificing anode, so that the pipeline forms cathode to the ground, forming protection and corrosion mitigation.

Intelligent test pile is an essential device in pipeline cathodic protection intelligent detection management system. It is mainly used for the detection of cathodic protection effect and operating parameters. Generally, one test pile is set along 1 ~ 2km of pipeline.

In the past, cathodic protection test piles were mostly tested manually by multimeter and tester (as shown in the figure above), which resulted in low efficiency, poor reliability and high risk, and was difficult to meet the requirements of cathodic protection monitoring of pipelines.

The intelligent test pile automatically collects the data of pipeline protection potential, corrosion current, pipeline spontaneous potential, anode spontaneous potential and battery voltage of the equipment at a regular time every day, and uploads the data to the cloud server regularly through the 4G/ NB-iot network.

The pipeline cathodic protection intelligent monitoring management system software is installed on the cloud server. The software is designed with B/S (browser/server) structure, and stores massive data with SQLSERVER database. It provides electronic map, data display, over-limit alarm, data query and various statistics and analysis functions. Support computer and mobile phone APP remote access.

The intelligent test pile is divided into two parts: the bolt body and the protective cover. The battery-powered intelligent monitor is installed in the protective cover to realize the functions of automatic data collection, automatic line switching, regular data uploading, and timely alarm of anomalies.

(1) Product specifications

◆ Standard specification: φ 108mm(diameter)*3000mm(height)

◆ Other specifications: customizable.

(2) Main functions

◆ Data collection: the data of cathodic protection parameters, battery voltage and measurement point signal quality are collected automatically.

Wireless communication: use 4G (Mobile/Unicom/Telecom) or NB-iot wireless network to report monitoring data regularly.

Data storage: the machine circulates to store the monitoring data, without loss in power failure.

◆ Abnormal alarm: If the potential/current exceeds the standard or the battery voltage is too low, an alarm is reported immediately.

Equipment protection: the cathodic protection circuit and all kinds of cables are protected to ensure the safety of equipment and convenient maintenance.

(3) Product features

High level of protection: waterproof, moisture-proof, dustproof.

Wide working temperature range: low temperature resistance, heat resistance.

◆ Micro power consumption operation: automatically wake up at regular time, collect + upload data; After the work is completed, the automatic sleep, power saving.

◆ Long battery life: battery life 3~5 years (related to the frequency of data reporting).

Large storage capacity: can store not less than 1 year of historical data.

◆ Easy maintenance: remote setting of working parameters, remote upgrade program.

(4) Technical parameters

◆ Monitoring parameters:

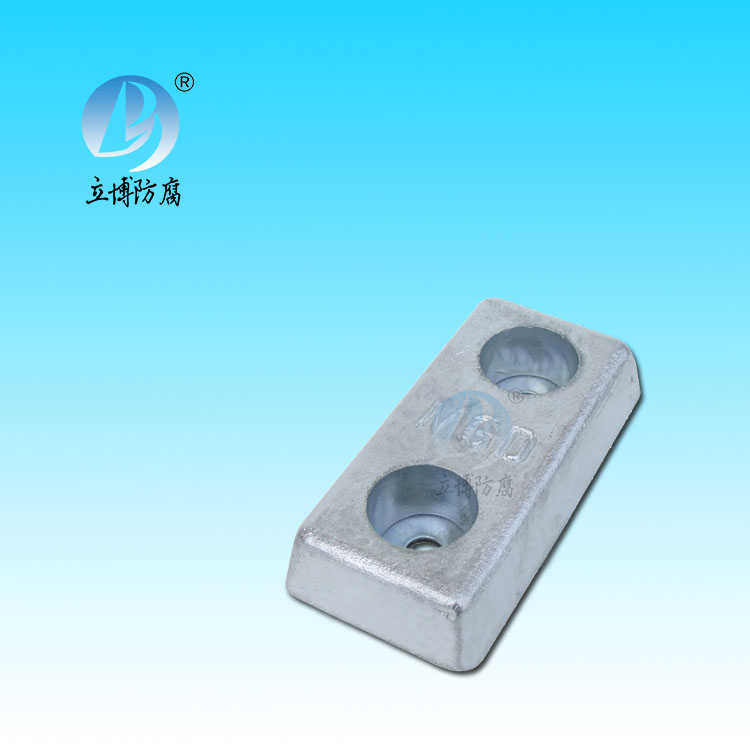

Sacrificial anode test pile: pipeline protection potential, corrosion current, pipeline potential, anode potential.

(2) Potential test pile (potentiostat method) : pipeline protection potential, pipeline potential.

◆ Voltage measurement range: -5 ~ 5V (customizable).

◆ Current measurement range: -2 ~ 2A (customizable).

Communication mode: 4G all-netcom (Mobile/Unicom/Telecom) or NB-iot.

◆ Protection grade: IP68.

◆ Standard battery: 20Ah/14.4V

◆ Working temperature: -40 ~ +85℃

◆ Working humidity: ≤95%.

客服QQ

客服QQ