News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

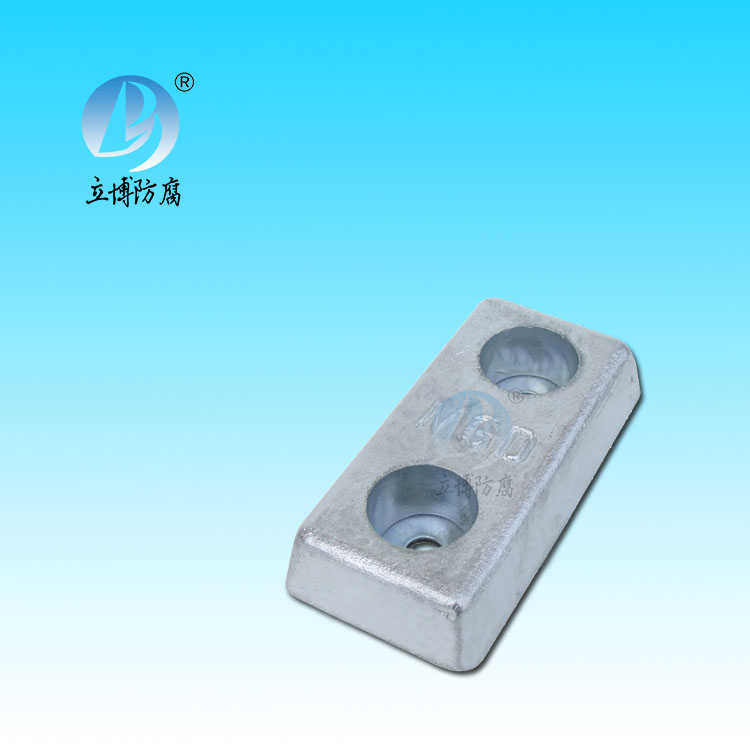

Aluminum alloy sacrifice anodes are installed underwater on steel piles

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-06-10

- Click:0

Implementation standard:

U.S.M il - A - 18001 k/W/GB4948-2002

Main performance:

Low driving voltage, light weight, high current efficiency.

Scope of application:

Aluminum alloy sacrificial anode is suitable for cathodic protection against corrosion of metals in ships, machinery and equipment, Marine engineering and harbor facilities in seawater medium, as well as pipelines and cables in sea mud.

Product features:

The most commonly used aluminum alloy anodes are Al-Zn-In and Al-Zn-Hg anodes, which are suitable for cathodic protection of structures such as ships, wharves, ports and Marine facilities, seawater cooling water systems and water storage tanks. AZI sacrificial anodes are cast by alloying high purity aluminum, zinc, indium and other metals. Aluminum alloy anode production gb4948-2002 "aluminum - zinc - indium alloy sacrifice anode".

Aluminum anodes produced by our company can prevent corrosion of steel structure in seawater, and are widely used in hull, pressure tank, seawater pipeline, port terminal facilities, Marine engineering, drilling platform, condenser and soil media pipeline corrosion. The performance of aluminum anode is affected by the chemical composition of the alloy, so we provide different composition of aluminum alloy combination to meet customer requirements, our company is currently implementing GB/T 4948-2002, U.S.Mil-A-18001K, W and other standards.

Product category:

(1) Ordinary aluminum alloy sacrifice anode (2) high activation aluminum alloy sacrifice anode (3) high efficiency aluminum alloy sacrifice anode (4) high temperature resistant aluminum alloy sacrifice anode (5) bracelet aluminum alloy sacrifice anode

Our company can also design and produce a variety of special specifications and performance of aluminum alloy sacrifice anodes according to the different needs of customers.

Scope of use:

Aluminum alloy sacrificial anode is suitable for cathodic protection against corrosion of metals in ships, machinery and equipment, Marine engineering and harbor facilities in seawater medium, as well as pipelines and cables in sea mud.

Aluminum sacrifices the environment of the anode

Cathodic protection for most metal installations in seawater or the internal floor of crude oil storage tanks cannot be used in soils with low chloride content. The electrode potential of the aluminum sacrificial anode is -1.05 volts. When the ambient temperature is higher than 49 degrees Celsius, the capacitance of the aluminum sacrificial anode decreases with the increase of temperature. The formula can be referred to: Z=2500-27 (T-20), T anode working temperature, unit of ℃. In salty water, the current capacity of the aluminum sacrificial anode may be reduced by half. The aluminum sacrificial anode can be fixed directly to the equipment structure to be protected without the need for other materials as fillers.

Main uses:

Aluminum anode can prevent corrosion of steel structure in seawater and fresh water. It is suitable for cathodic protection of metal corrosion of ships, machinery and equipment, Marine engineering and harbor facilities in seawater medium, as well as seawater pipelines, hulls, pressure tanks, storage tanks, drilling platforms, pipelines and cables in sea mud. The performance of the aluminum anode is influenced by the chemical composition of the alloy. We offer different alloy compositions to meet the customer's requirements. We can also manufacture anodes with special chemical composition according to the customer's requirements.

Specification: 16 kg, 22 kg, 23 kg, 35 kg, 50 kg, 85 kg, 120 kg, 131 kg, 180 kg

Technical requirements for sacrificial anode welding

Chemical composition

| Zn | In | Cd | Sn | Mg | Si | Ti | Impurities, not greater than | Al | ||

Si | Fe | Cu | |||||||||

Al-Zn-In-Sd | 2.5-4.5 | 0.018-0.050 | 0.005-0.020 | - | - | - | - | 0.10 | 0.15 | 0.01 | allowance |

Al-Zn-In-Sn | 2.2-5.2 | 0.020-0.045 | - | 0.018-0.035 | - | - | - | 0.10 | 0.15 | 0.01 | allowance |

Al-Zn-In-Si | 5.5-7.0 | 0.025-0.035 | - | - | - | 0.10-0.15 | - | 0.10 | 0.15 | 0.01 | allowance |

Al-Zn-In-Sn-Mg | 2.5-4.0 | 0.020-0.050 | - | 0.025-0.075 | 0.50-1.00 | - | - | 0.10 | 0.15 | 0.01 | allowance |

Al-Zn-In-Mg-Ti | 4.0-7.0 | 0.020-0.050 | - | - | 0.50-1.50 | - | 0.01-0.08 | 0.10 | 0.15 | 0.01 | allowance |

電化學性能

| The open circuit potential-V(SCE) | Work potential-V(SCE) | Actual capacitanceA·h/kg | Current efficiency% | soluble |

1.10-1.18 | 1.05-1.12 | ≥2400 | ≥85 | The corrosion products are easy to fall off and the surface dissolution is uniform. | |

High efficiency aluminum sacrifice anode | 1.10-1.18 | 1.05-1.12 | ≥2600 | ≥90 | |

High activated aluminum alloy sacrifice anode | 1.45-1.50 | 1.40-1.45 | ≥2080 | ≥70 |

Models and specifications of sacrificial anodes commonly used in port and Marine engineering facilities

| specifications/mm | The weight of thekg |

Length × (top bottom + bottom bottom) × heightmm | ||

AI-1 | 2300×(220+240)×230 | 310.0 |

AI-2 | 1600×(200+210)×220 | 190.0 |

AI-3 | 1500×(170+200)×180 | 130.0 |

AI-4 | 900×(150+170)×160 | 58.0 |

AI-5 | 1500×(148+178)×170 | 120.0 |

AI-6 | 850×(180+220)×180 | 85.0 |

AI-7 | 800×(200+280)×150 | 80.0 |

AI-8 | 700×(160+220)×180 | 72.5 |

AI-9 | 1250×(115+135)×130 | 56.0 |

AI-10 | 1000×(115+135)×130 | 46.0 |

AI-11 | 750×(115+135)×130 | 35.0 |

AI-12 | 500×(115+135)×130 | 23.0 |

客服QQ

客服QQ