News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

What is the effect of pipeline anticorrosion?

- Author:Libo

- Source:wwww.rankebio.com

- Date:2021-08-10

- Click:0

Pipeline anticorrosion is to prevent the pipeline from chemical or electrochemical reaction corrosion.

The term "corrosion Prevention of pipes" refers to measures to slow or prevent the corrosion and deterioration of pipes under the chemical and electrochemical action of internal and external media or by the metabolic activity of microorganisms.

The anti-corrosion methods

Anticorrosion coating

It is one of the most basic methods of pipeline anticorrosion to apply the coating evenly and compactly on the surface of the derusted metal pipeline to isolate it from various corrosive media. Since the 1970s, more requirements have been put forward for coating properties due to the installation of pipelines in harsh environments such as polar regions and oceans, and the increase of pipeline temperature due to the heating and transportation of oil products. Therefore, more and more composite materials or composite structures are used in pipeline anticorrosive coatings.

1, outer wall anticorrosive coating: pipe outer wall coating material type and use conditions.

(2) Inner wall anticorrosive coating: in order to prevent corrosion in the tube, reduce friction resistance, improve the throughput and coated on the inner wall of the tube film. Commonly used coatings are amine cured epoxy resin and polyamide epoxy resin, coating thickness of 0.038 ~ 0.2 mm. Surface treatment must be carried out on the inner wall of the pipe to ensure that the coating is firmly bonded to the pipe wall. Since the 1970s, the same materials have been used to coat the inner and outer walls, so that the inner and outer walls can be coated at the same time.

(3) Anticorrosion and insulation coating: in the pipeline of medium and small diameter heat transport crude oil or fuel oil, in order to reduce the heat dissipation of the pipeline to the soil, the composite layer of insulation and anticorrosion is added on the outside of the pipeline. The commonly used insulation material is rigid polyurethane foam, applicable to the temperature of -185 ~ 95℃. To enhance the strength of the soft material, a layer of high-density polyethylene is added to the insulation layer to form a composite structure to prevent groundwater from seeping into the insulation.

Electrical method to protect

Pipeline anti-corrosion (Figure 3)

A method of protecting a metal from corrosion by changing the electrode potential of the metal relative to the surrounding medium. Electrical protection of long distance pipeline only refers to cathodic protection and corrosion prevention.

(1) Cathodic protection: the method of polarizing the protected metal into a cathode to prevent metal corrosion. This method has been used for ship corrosion protection for more than 150 years; In 1928, it was first used for pipelines. The principle that the cathode of a metal corroded battery is not corroded while the anode is corroded is applied to the metal anticorrosion technology. By applying an external current to force the entire cathodic polarization of the protected metal surface in the electrolyte, corrosion will not occur. There are two indicators to judge whether the pipeline achieves cathodic protection. The first is the minimum protective potential, which is the potential of the cathode polarization of the metal in the electrolyte until the corrosion process stops. Its value is related to factors such as the environment, and the commonly used value is -850 millivolts (relative to the copper - copper sulfate reference electrode measurement, the same below). The second is the maximum protective potential, that is, the maximum potential value of the surface of the protected metal. When the cathode polarization is too strong, hydrogen will precipitate between the pipe surface and the coating, resulting in the cathode stripping of the coating. Therefore, the confluence potential must be controlled within the allowable range to prevent the coating from being damaged. This value is related to the properties of the coating, generally between -1.20 to -2.0 volts. There are two ways to realize cathodic protection of underground pipeline: impressed current method and sacrificial anode method.

Impressed current method is the use of DC power supply, the negative electrode is connected to the protected pipeline, the positive electrode is connected to the anode bed. After the circuit is connected, the pipe is polarized by the cathode. Complete cathodic protection is obtained when the pipe reaches the minimum protection potential to ground. Its wiring is shown in Figure 3. The common DC power supply can be used, especially the rectifier. The DC output is generally below 60 volts and 30 amps. The new type of DC power supply has temperature difference generator, solar cell and so on. The anode ground bed is connected with the positive pole of the DC power supply, and the conductive body of good electrical contact with the earth, or called the anode ground device; Commonly used materials are carbon steel, high silicon iron, graphite, magnetic iron oxide, etc. Anodic ground beds are located where the soil resistivity is low and the protective current is easily distributed without interfering with adjacent underground structures. The anode corresponds to the buried position of the pipeline, there are two kinds of shallow buried long distance anode and deep anode. In order to measure the cathodic protection parameters and to evaluate the cathodic protection effect of the pipeline, detection points and inspection sheets should be set along the pipeline. Supporting the use of testing instruments are high resistance voltmeter, ammeter, copper sulfate electrode, etc. Since the 1970s, the cathodic protection parameter telemetry system combined with the pipeline air patrol line has been adopted to process the measured data with an electronic computer. Impressed current cathodic protection of a single station protection distance can generally reach tens of kilometers, long distance pipeline cathodic protection with this method.

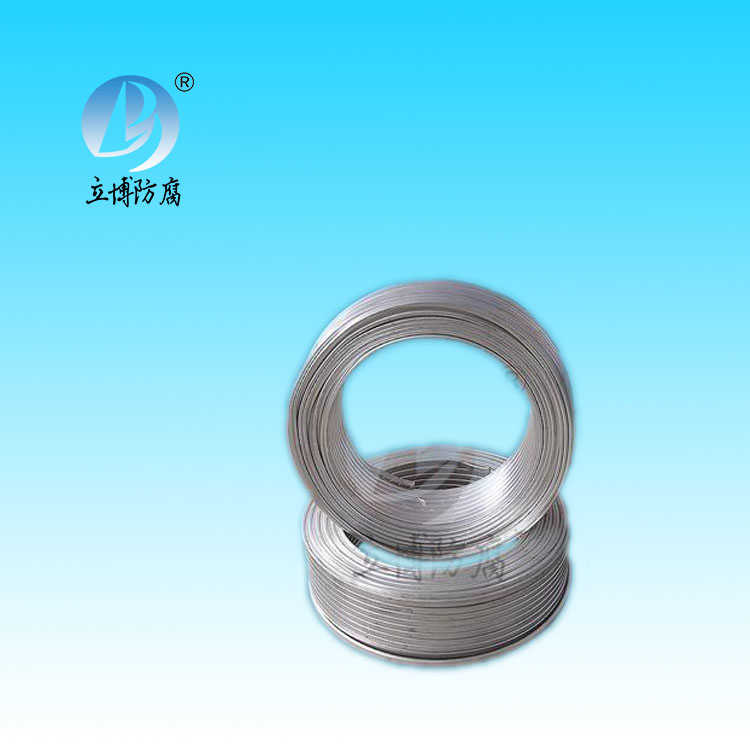

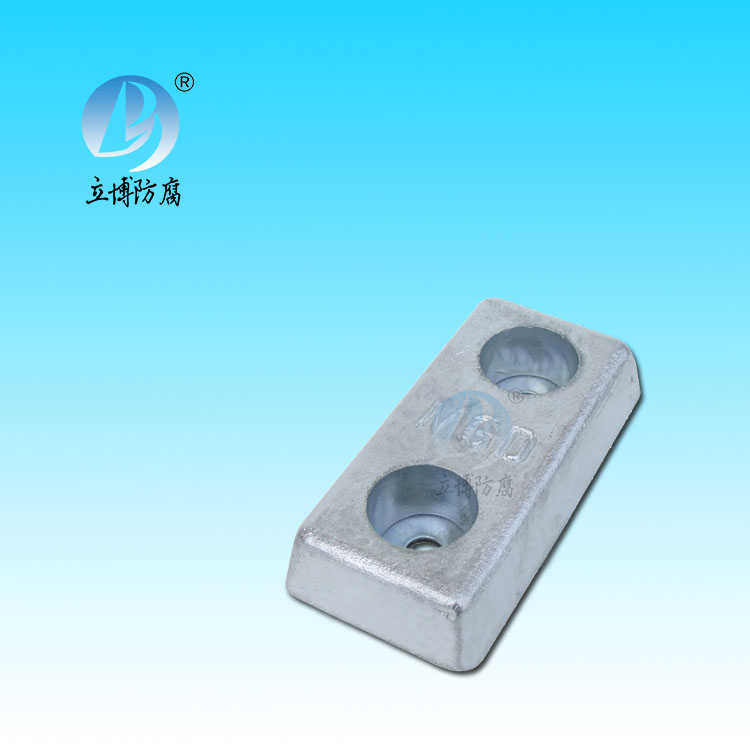

The sacrificial anode method is to use a metal with a more negative potential than the protected metal electrode to connect with the protected metal, and the two form a galvanic cell in the electrolyte. The metal with a negative potential (such as magnesium, zinc, aluminum and its alloy) becomes the anode, which is gradually lost in the process of output current. The pipe metal being protected becomes the cathode to avoid corrosion, so the metal with a negative potential is called the sacrific anode. Its wiring is shown in Figure 4. The underground pipeline adopts sacrificial anode protection, the decisive factors of which are the anode current, the number of anodes and the protection length. When the type of anode is determined, the above parameters are affected by the grounding resistance of the anode and the leakage resistance of the section with the anode protection. The former depends on the soil resistivity, the latter depends on the resistance of the pipe coating and the construction quality of the coating. The service life of sacrificial anodes is weight dependent and can be used from several years to several decades as required. Sacrific anode is widely used in underground metal pipeline anticorrosion because of its advantages such as saving investment, simple management, no need for external power supply and good anti-interference corrosion effect.

(2) corrosion prevention method: one is to take measures on the relevant facilities of the stray current source to reduce the leakage current to a minimum; Second, when laying pipelines, avoid stray current areas as far as possible, or improve the quality of the insulation and anticorrosion layer of the disturbed pipe section, using shielding, installing insulation flange and other measures; The third is for the interference pipeline drainage protection, that is, the stray current from the interference pipeline is discharged back to the leakage current of the power grid, in order to eliminate the stray current on the pipeline corrosion. According to the application range and the different performance of the discharge equipment, there are three kinds of direct discharge, polar discharge and forced discharge. For the protection of ac interference voltage, many countries have formulated technical regulations, mainly using two methods of safe distance and pipeline discharge to prevent the pipeline from damage.

客服QQ

客服QQ